WORM GEAR

Customized Worm Gear Solutions

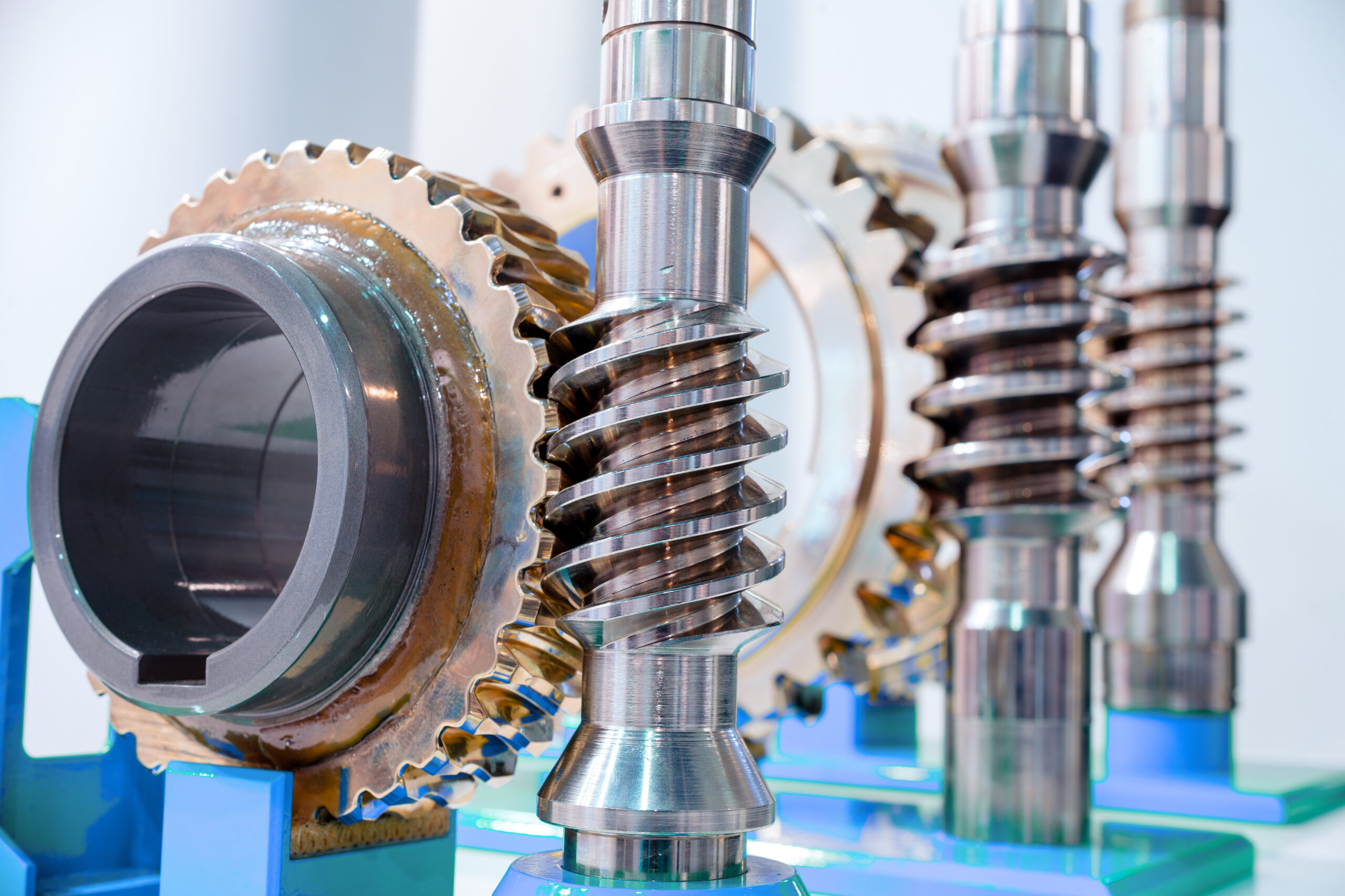

Worm gears are suitable for applications where there is a need for significant transmission ratios, operating at low speeds, and handling substantial torques.

Worm Gear

Worm gears find their primary utility in scenarios demanding substantial transmission ratios, operating at reduced speeds, and managing notable torques. The characteristic sliding movement inherent to this gearing style is considerably pronounced. In addition to the worm gears in Belon gear range, we also manufacture workpieces to suit customer specifications. We would gladly design the engineering parameters on your behalf.

Worm Shaft

There exist two primary classifications of worm gear shafts: straight and tapered. Predominantly, straight worm gear shafts are encountered due to their ubiquity. They find utility in scenarios where the worm gear's motion necessitates a linear trajectory. Conversely, tapered worm gear shafts find purpose in situations mandating a rotational path with curvature.

The dimensions of the worm gear shaft are contingent upon the dimensions of the worm gear itself, as well as the quantum of torque it is mandated to convey. This torque-bearing capacity is crucial to ensure the worm gear shaft remains unyielding and unbroken in the face of mechanical stress. The worm gear transmission system's effectiveness hinges upon the durability, alignment, and force transmission facilitated by the worm gear drive shaft, which thereby assumes a critical role in the entirety of the worm gear mechanism.

| Data | |

| Mofulus Max. | 35 |

| Diameter Max. | 3000mm |

| Quality | DIN4 |

| Start Count Max |

12 |

| Shaft Length | 4500mm |

Worm gears find their primary utility in scenarios demanding substantial transmission ratios, operating at reduced speeds, and managing notable torques. The characteristic sliding movement inherent to this gearing style is considerably pronounced.

The production of worm gears commonly involves the use of a hobbing process, employing a cutting tool or hob that closely resembles the worm intended to mesh with the gear. The worm itself can undergo various machining techniques, such as turning, hobbing, milling, or grinding.

At Belon, we possess the expertise to craft worm gears in tailor-made dimensions.

Possessing over 300 sets of various inspection and production equipment such as specialized CNC machines for planar double-envelope processing, worm grinding machines, and boring machines. Leveraging the extensive experience of our adept team and our substantial array of equipment, we adeptly manufacture gears of superior quality, marked by exceptional precision.

.

| Data | |

| Mofulus Max. | 35 |

| Diameter Max. | 3000mm |

| Quality | DIN4 |

| Start Count Max |

12 |

| Shaft Length | 4500mm |