CYLINDRICAL GEAR

Spur Gear

Spur gears have straight teeth and are the most common type of gear. They are used to transmit motion between two parallel shafts and are known for being highly efficient and producing a lot of power.

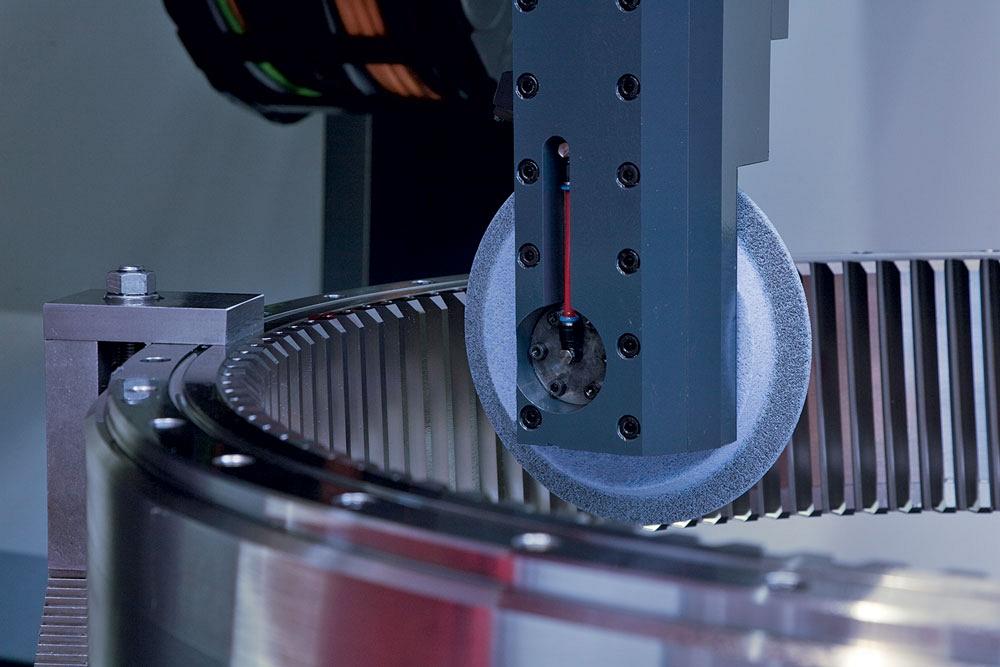

Belon Customization's spur gears are distinguished by their exceptional precision, durability, and reliability, ensuring seamless and efficient power transmission across diverse industrial sectors.With expertise in crafting high-precision and top-tier gears, Belon specializes in manufacturing a broad spectrum of sizes and volumes. Our custom spur gears are meticulously crafted using state-of-the-art gear grinding and cutting techniques, tailored to meet precise specifications.

| Milling | Hobbing | Shapping | Grinding | |

| Mofulus Max. | 35 | 35 | 24 | 40 |

| Outer Diameter Max. | 5000mm | 1200mm | 2000mm | 5000mm |

| Face Width | 2200mm | 1600mm | 1100mm | 2200mm |

| Quality |

DIN3962 CLASS7 |

DIN3962 CLASS7 |

DIN3962 CLASS8 |

DIN3962 CLASS3 |

| Surface Finish | Ra3.2 | Ra3.2 | Ra3.2 | Ra0.4 |

| Max Helical Angle | +30 °/-45° | ±45° | 0° | ±45° |

Helical Gear

Helical gears, in contrast to spur gears, provide superior load-carrying capacity and smoother operation, resulting in minimized wear and noise levels. Moreover, the higher contact ratio of helical gears ensures a more even distribution of the load across numerous teeth, leading to enhanced durability and reduced wear. Additionally, the remarkable design precision and flexibility of helical gears make them an ideal and versatile choice for a wide array of applitions.

Belon stands ready with comprehensive capabilities to meet all your helical gear manufacturing needs, offering both cut and precision ground gears to exacting specifications.

| Milling | Hobbing | Shapping | Grinding | |

| Mofulus Max. | 35 | 35 | 24 | 40 |

| Outer Diameter Max. | 5000mm | 1200mm | 2000mm | 5000mm |

| Face Width | 2200mm | 1600mm | 1100mm | 2200mm |

| Quality |

DIN3962 CLASS7 |

DIN3962 CLASS7 |

DIN3962 CLASS8 |

DIN3962 CLASS3 |

| Surface Finish | Ra3.2 | Ra3.2 | Ra3.2 | Ra0.4 |

| Max Helical Angle | +30 °/-45° | ±45° | 0° | ±45° |

Custom Gear Manufacturing

Spur Gear, Helical Gear, Internal Gear, Herringbone Gear

As a specialized Chinese manufacturer and supplier of custom gears, we are committed to delivering reliable and cost-effective high-precision gear solutions, ensuring our customers' utmost satisfaction..

Internal Gear

Internal gears, distinct from external gears, feature teeth cut along their inner surface instead of the outer surface. These internal gears are designed to mesh seamlessly with external gears, facilitating the efficient transmission of motion and power in diverse mechanical systems.

Belon, with its extensive experience as a ring gear manufacturer spanning decades, employs cutting-edge materials and advanced production technology to guarantee the utmost durability of its products. Our specialized capabilities enable us to produce a wide range of ring gears tailored precisely to meet the unique requirements of our valued customers. As a result of our proficiency in ring gear production, we have earned a reputation as a trusted and dependable partner for any mechanical system, providing the essential components to ensure optimal performance and reliability.

| Milling | Shapping | Grinding | |

| Mofulus Max. | 35 | 24 | 35 |

| Outer Diameter Max. | 5000mm | 2400mm | 5000mm |

| Face Width | 2200mm | 1100mm | 2200mm |

| Quality |

DIN3962 CLASS8 |

DIN3962 CLASS8 |

DIN3962 CLASS4 |

| Surface Finish | Ra3.2 | Ra3.2 | Ra3.2 |

| Max Helical Angle | +30 °/-45° | 0° | ±45° |

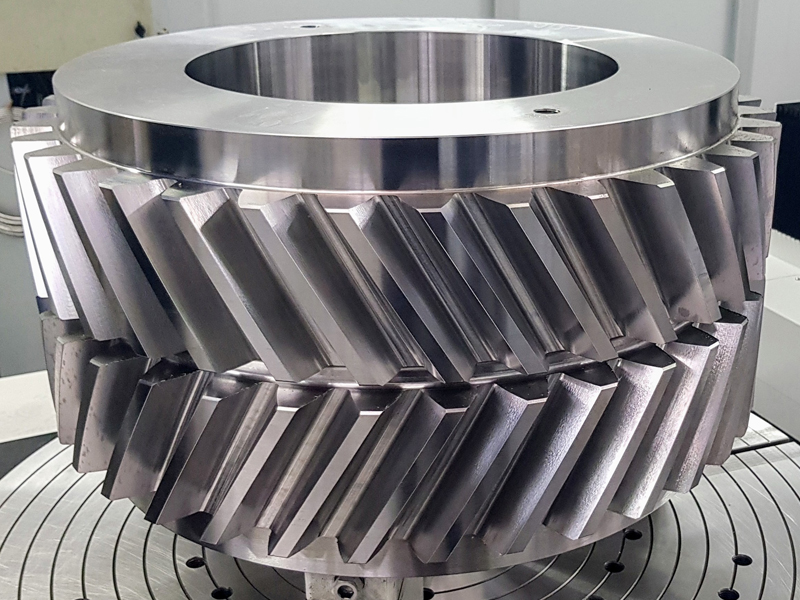

Herringbone Gear

A herringbone gear, which falls under the category of double helical gears, is a unique gear design featuring the combination of two helical gears with opposite hands positioned side by side, not face to face.

Belon as a distinguished manufacturer and supplier of herringbone gears, holds a leading edge in both heat treatment and gear cutting techniques. Our team of experts is committed to maintaining stringent quality control and inspection measures, ensuring that each gear undergoes thorough scrutiny to meet the highest precision and durability standards. With a relentless dedication to quality and a focus on innovation, we deliver dependable and cost-effective herringbone gears, catering to the diverse needs of various industries.

| Milling | Hobbing | Shapping | Grinding | |

| Mofulus Max. | 35 | 35 | 24 | 40 |

| Outer Diameter Max. | 5000mm | 1200mm | 2000mm | 5000mm |

| Face Width | 2200mm | 1600mm | 1100mm | 2200mm |

| Quality |

DIN3962 CLASS7 |

DIN3962 CLASS7 |

DIN3962 CLASS8 |

DIN3962 CLASS3 |

| Surface Finish | Ra3.2 | Ra3.2 | Ra3.2 | Ra0.4 |

| Max Helical Angle | +30 °/-45° | ±45° | 0° | ±45° |