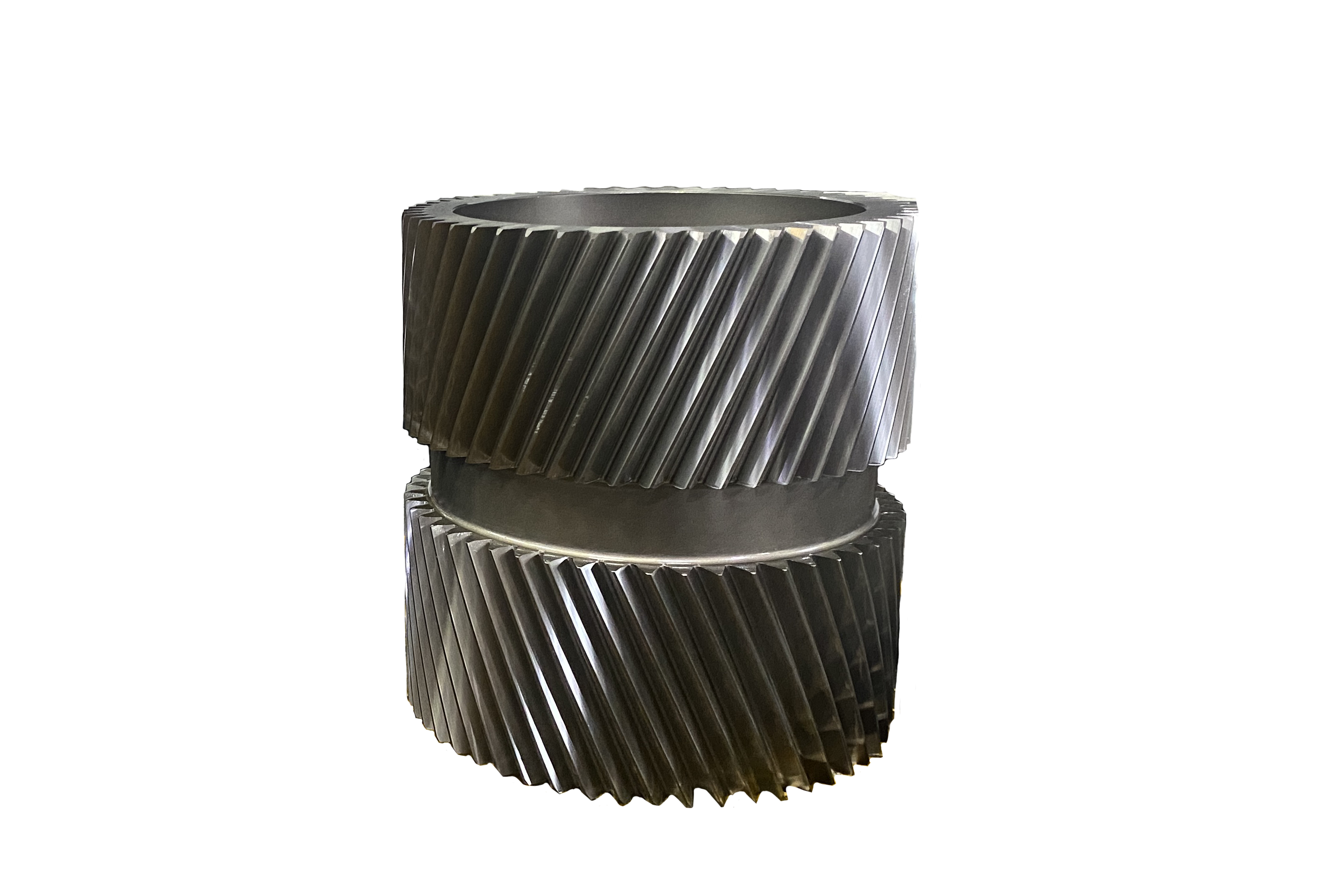

Grinding double Helical Gear

Grinding double Helical Gear

⚙Module: 8 ⚙Application: Mining

Material: 18CrNiMo7-6

Heat treatment: Carburizing

Accuracy: DIN6

Double helical gears known for their unique design, which features two sets of teeth that are helically arranged in opposite directions. This design helps to eliminate the axial thrust forces and reduces noise and vibration, making double helical gears an ideal choice for high-speed and high-torque applications.

The grinding process plays a critical role to ensure the precision and accuracy of double helical gears. Grinding gears to achieve the required accuracy DIN5-6.

This level of precision ensures that the gears are manufactured to tight tolerances, resulting in minimal variation in tooth profiles and alignment. As a result, gears with a DIN6 accuracy rating offer superior performance, reduced wear, and extended service life.